Book Appointment Now

A Bathroom Cabinetry Packaging Machine for Modern Production Lines

Explore a bathroom cabinetry packaging system designed for factories with 10–20k ㎡ monthly capacity—featuring light curtain measurement and see how it play a vital role in bathroom vanities factory.

Precision and Flexibility in Bathroom Cabinetry Packaging

As product variation increases in the bathroom cabinet market, packaging workflows must adapt to meet rising complexity and volume. A new generation of bathroom cabinetry packaging machines is helping manufacturers simplify operations without sacrificing precision or speed.

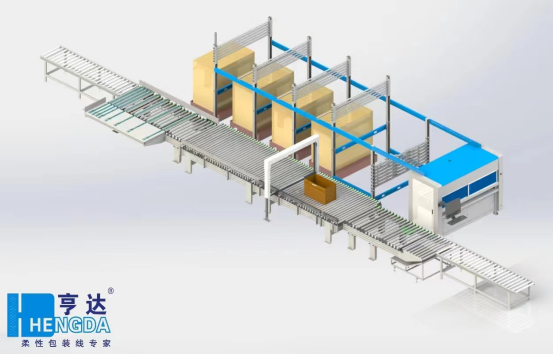

One standout packaging solution from Hengda—the Dual-workstation Carton Packaging Line with Light Curtain Measurement—offers a compact, high-throughput solution for facilities producing 10,000–20,000 ㎡ of cabinetry per month.

Core Benefits of This Packaging System

Minimal Footprint, Maximum Output

Requiring only 18×6 meters of floor space and operated by 2–3 workers, this packaging machine is ideal for medium-to-large scale factories seeking efficiency without overautomation.

With two loading workstations operating in parallel at the same time, utilizing the efficiency of the packaging production line. Production teams can handle fluctuating order volumes without bottlenecks or wasting unnecessary time.

Accurate Measuring System Without Software Complexity

A light curtain measuring machine precisely detects the cabinet size by infrared light and instantly triggers right-sized carton creation by box making machine. This allows every bathroom cabinet to be packaged securely and efficiently—no excess filler, no overboxing.

Unlike software-bound automation, this system is plug-and-play, eliminating the need to dock with ERP or MES systems. Deployment is fast, and operators can manage the line with minimal training.

Well-Matched Components for Consistent Performance of The Whole Packaging Line

The intelligent bathroom cabinetry packaging line setup includes:

• Carton Making Machine – Automatic cuts, scores, creases the packaging cartons on demand

• Power Palletising Table – For fast and efficient loading

• Light Curtain Measuring Machine – Detect the size and delivers precise size data in real-time

• Plate Feeder – Supports stable cabinet panel delivery

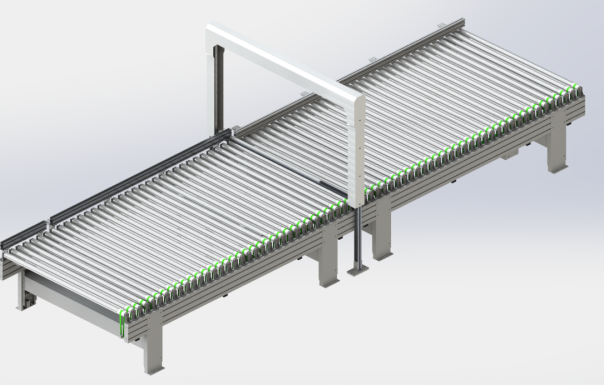

• Non-powered Roller Conveyor – Ensures smooth package flow

This modular integration packaging line ensures that each step supports the next, with minimal downtime or manual rework.

Case Highlight: A Proven Setup for Bathroom Cabinetry Factory

A well-known bathroom vanities factory SSWW implemented this exact packaging system to streamline its bathroom furniture packaging process. The results:

• 50%+ faster packaging cycle times

• Over 40% savings in cardboard and other packing materials

• Zero reliance on preset box inventory • Tidy and high end package appearance

This seamless intelligent packaging line for bathroom vanities has allowed their team to shift from fixed-size cartons to fully adaptive packaging, meeting daily production goals with fewer hands and higher consistency.

Intelligent Packaging That Matches Customization

Today’s bathroom cabinetry production is more diverse and fast-paced than ever. An easy-to-use packaging machine with light curtain guidance enables factories to align packaging flow with modern cabinet output.

With a modest investment, mid-sized factories can gain a scalable edge—cutting costs, speeding delivery, and ensuring brand-quality presentation with every package.

Ready to upgrade your cabinet packaging? Let’s talk about how this solution fits your production floor.