Book Appointment Now

Custom Cabinets Packaging Deserve Custom-Fit—Automated, Right-Sized, And Scalable

Every kitchen is unique. Your packaging should be too. New packaging way for custom cabinets is growing. Discover how custom kitchen cabinet packaging helps manufacturers reduce material waste, streamline production, and protect high-value cabinet shipments.

Precision Packaging Boosts Operational Efficiency

Custom kitchen cabinets vary by order—dimensions, components, finishes, and accessories all change. Traditional fixed-size cartons fail to accommodate this variation without excess filler or damage risk.

With on-demand custom packaging system, manufacturers produce right-sized boxes for every order, eliminating time spent sorting through pre-stocked packaging and reducing labor demands on the floor.

One cabinet plant that integrated automated packaging machine with its production software saw a 40% reduction in manual packaging time, improving daily throughput without adding headcount.

Right-Sized Boxes Lower Damage Rates and Return Costs

Poorly fitted cartons are a hidden expense. Oversized boxes create shifting during transit, leading to scratched panels, broken corners, and hardware loss. Automated custom kitchen cabinet packaging systems build cartons in accordance with the exact dimensions of the items. The result: reduced in-carton costs, material costs, transit damage, fewer returned shipments, and stronger customer satisfaction. Proudly say, the cabinet manufacturers who purchased Hengda Automatic Packaging System all totally eliminate internal rework requests after switching to right-sized corrugated packaging lines. Not only boosting their profits, but also getting recognized by their customers.

Packaging Automation Cuts Material Waste and Storage Needs

Stocking dozens of carton sizes used to be a logistical burden. Pallets of unused boxes took up valuable warehouse space—and half of them didn’t fit the order properly.

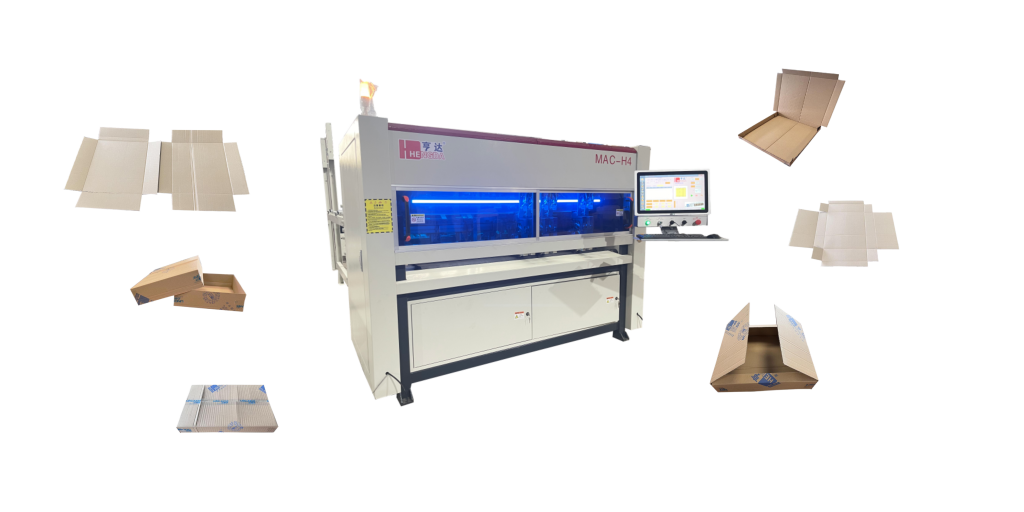

Now, manufacturers store corrugated material in flat stacks and convert it into exact-fit boxes on demand, freeing up storage, reducing scrap, and improving sustainability metrics. Some cabinet factories still cut the cardboard and pack the products by labor, so that the utilization of the cardboard is very low and the quality of the carton is very low as well, like burrs, uneven folds, corners without edges. With carton packaging machine, no need to prepare box inventory but give you the perfect carton appearance, cutting, scoring, creasing all in one compact machine.

Several production lines using automated packaging have reported up to 30% reduction in cardboard consumption and near-zero need for void-fill materials.

Integration with Enterprise Resource Planning System Simplifies Workflow

Hengda packaging systems integrate directly with cabinet design and ERP software. When a cabinet order is finalized, dimensional data automatically flows into the packaging station.

This data-driven setup enables just-in-time packaging production, matching every kitchen set’s packaging to its actual bill of materials—no delays, no manual input, no mismatch.

This kind of automation is especially beneficial for manufacturers running “lot size 1” production for fully customized kitchens.

Sustainable, Scalable, and Ready for Growth

Sustainability isn’t just a trend—it’s a customer expectation. Custom kitchen cabinet packaging reduces waste, shrinks carbon footprint, and contributes to corporate ESG goals. And as demand for personalized cabinets grows, automated packaging systems scale effortlessly, adapting to shifting product lines without the need for major retooling.

Packaging That Keeps Pace with Customization

Today’s cabinet industry requires agility—not just in design and manufacturing, but in packaging too. Custom kitchen cabinet packaging delivers that agility, allowing manufacturers to align packaging with production in real time.

Whether the goal is to cut costs, reduce waste, or improve delivery experience, right-sized, automated packaging has become a strategic advantage in the competitive cabinet market.

Curious how this can work in your facility? Reach out to learn how right-sized packaging can transform your cabinet line operations.