Book Appointment Now

How Custom Kitchen Cabinet Packaging Is Transforming Logistics Efficiency

Discover how custom kitchen cabinet packaging improves logistics by reducing waste, increasing flexibility, and aligning with modern manufacturing needs.

In today’s era of personalized living spaces, kitchen cabinets are no longer mass-produced and identical. Manufacturers are producing tailor-made cabinet systems for unique layouts, designs, and finishes. However, this shift demands a smarter, more adaptive approach to logistics. Custom kitchen cabinet packaging offers a transformative solution—one that enhances protection, reduces costs, and improves operational flow from factory to front door.

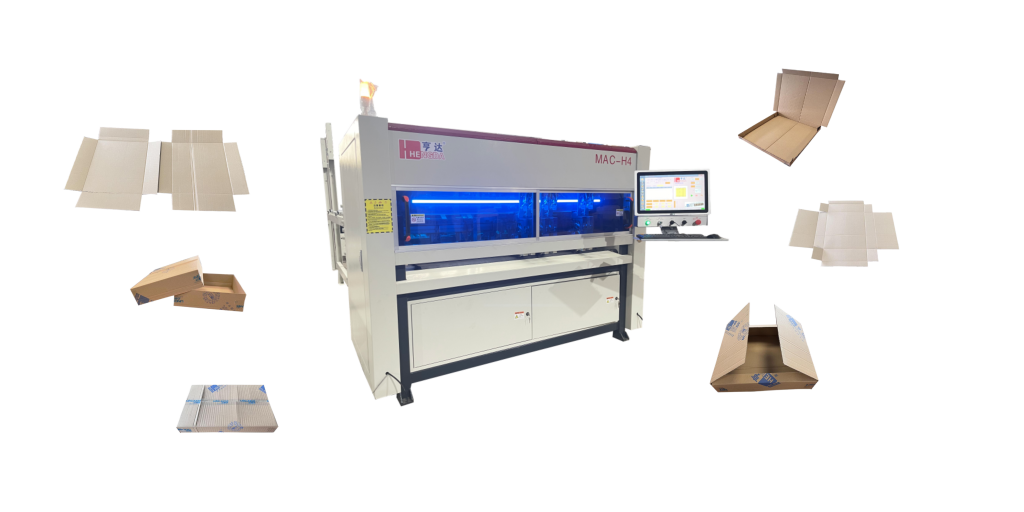

The Role of Automatic Packaging in Kitchen Cabinet Manufacturing

In the world of custom kitchen cabinetry, no two shipments are the same. Automatic carton packaging solution provides the necessary flexibility to match this production model.

Built for Flexibility

Unlike rigid, pre-ordered cartons, automatic packaging is formed on-demand based on real-time dimensions. It adapts to various panel sizes, configurations—minimizing void space and eliminating the need for excess filler.

Custom Fit = Better Protection

Each piece of cabinetry, whether flat-packed or semi-assembled, is enclosed in precisely formed packaging by intelligent packaging solutions. This results in fewer product damages, stronger customer satisfaction, and lower return rates.

Boosting Efficiency Through Automation

Modern cabinet manufacturers are moving toward automatic packaging machines that integrate directly with production lines.

Data-Driven Packaging Creation

Packaging machines now receive dimensions with various methods, whether directly from the ERP system or measured by the size measuring machine. This automated connection enables the creation of the right box, in the right shape, at the right moment.

Reduced Labor and Material Costs

Manual packaging workflows often require multiple workers and large areas for sorting cartons. In contrast, automated packaging lines handle tasks faster, more consistently, and help you cut cost in corrugated cardboard and fillers.

Intelligent Custom Kitchen Cabinet Packaging Reduces Waste and Cost

Traditional custom kitchen cabinet packaging isn’t just flexible—it’s also cost-effective. Intelligent packaging solutions aren’t just more flexible—they’re also more economical and environmentally friendly.

Material Savings

By using only the required amount of corrugated cardboard, manufacturers can cut cardboard usage by up to 30%. This directly impacts both the cost of materials and shipping.

Sustainable Gains

Fewer materials mean less packaging waste, a smaller carbon footprint, and a stronger alignment with the green expectations of today’s buyers.

Optimized Shipping and Delivery

Efficient packaging leads to better stacking, optimized pallet loading, and reduced transportation volume.

Maximize Truck Space

Right-sized boxes help logistics teams make the most of each shipment, reducing the number of trucks on the road and lowering freight costs significantly.

Fewer Damages, Happier Customers

Tightly packed, form-fitting boxes provide maximum protection, reducing in-transit movement and ensuring that the final delivery meets showroom standards.

Packaging Is Now a Strategic Asset

In the world of modern kitchen design, packaging can no longer be an afterthought. Custom kitchen cabinet packaging is a competitive advantage that empowers manufacturers to cut waste, streamline workflows, and deliver a premium product experience from end to end. For companies embracing automation, corrugated flexibility, and data-driven workflows, the future of cabinet packaging is already here—and it’s reshaping the industry one box at a time. Hengda provides a wide range of packaging solutions, whether you’re looking for semi-automatic or fully automatic packaging machine, you can find the best solutions for your factory packaging.